| Ch 3. Beam Shear/Moment Diagrams | Multimedia Engineering Mechanics | ||||||

|

Shear and Moment |

Shear/Moment Diagrams |

Moving Loads |

|||||

| Shear/Moment Diagrams | Case Intro | Theory | Case Solution | Example |

| Chapter |

| 1. Stress/Strain |

| 2. Torsion |

| 3. Beam Shr/Moment |

| 4. Beam Stresses |

| 5. Beam Deflections |

| 6. Beam-Advanced |

| 7. Stress Analysis |

| 8. Strain Analysis |

| 9. Columns |

| Appendix |

| Basic Math |

| Units |

| Basic Mechanics Eqs |

| Sections |

| Material Properties |

| Structural Shapes |

| Beam Equations |

| eBooks |

| Dynamics |

| Fluids |

| Math |

| Mechanics |

| Statics |

| Thermodynamics |

| ©Kurt Gramoll |

|

|

||

| Introduction |

||

|

|

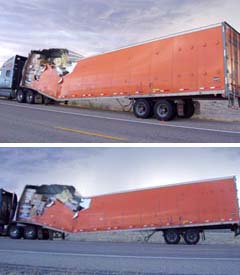

"Well, this is a new one for me" said the highway patrolman when he was called to investigate the accident. "I have never seen a semi snap in two due to the load. I wonder why it failed near the front and not in the middle?" His partner added, "I am sure the investigation team will let us know. I wonder if the truck was overloaded?" What is known:

|

|

| Question |

||

Assumed Location of Trailer Supports |

Does the failure location agree with a basic beam analysis? What is the value of the maximum bending moment and does it exceed the design moment of 200 kip-ft? |

|

| Approach |

||

|

||